After completing the tangential arm assembly checks and cleaning the Beogram 4002 cabinet, it was time to reinstall the floating chassis.

The reassembly began with cleaning and lubricating the three suspension lock down screws, then reinstalling them in the Beogram cabinet.

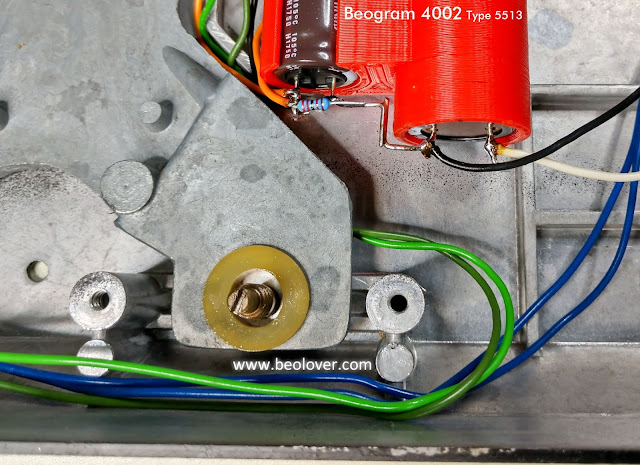

With all three suspension locks back in place, the platter motor and output board, which had been previously restored, were reinstalled.

The control panel, RPM indicator panel, and arm position scale were then put back in their respective places.

Prior to installing the platter, a power-on test was conducted to verify the functionality of the arm position and record detector sensors.

The arm position sensor was confirmed to be working correctly.

Both the 33⅓ RPM and 45 RPM speed selections, as well as the two new Beolover indicators, were also found to be operational.

The arm position sensor, along with the fixed arm record detection sensor, were inspected.

The arm position sensor, ES switch, SO switch, and tracking sensor were all functioning as expected. However, the fixed arm record detector lamp appeared dim.

Further testing with the platter installed confirmed that the sensor failed to detect the empty platter.

Upon inspection, the fixed arm lamp housing was opened, revealing that the lamp was barely illuminated.

The lamp was then removed, and a partial burnout was discovered.

Although the last Beolover LED record detection lamp assembly had been used, a few original Bang & Olufsen Beogram 4002 detector lamps were available.

With the new lamp installed, the sensor output was at the expected level.

The Beogram was ready to be moved to the testing bench for final adjustments, which included dialing in the sensor voltages, adjusting the platter speed, setting the tracking sensor sensitivity, and completing the service manual adjustments.