The Beogram 4002 I’m currently working on has a cracked hood around the hinge attachments. The left side was entirely detached, and the right side had a crack extending around one of the holes.

The right side had a crack going all the way around one of the attachment holes:

To begin, I glued the broken pieces back together using Weld-On #4 acrylic solvent. This low-viscosity solvent is ideal for injecting into cracks, as capillary action draws it in. This created a strong initial bond between the broken parts.

While this already creates a fairly strong bond, I reinforced the repair by applying thin patches to the cracked areas using Weld-On #16. These patches, made from 20 mil PETG sheet, were chosen for their thinness and compatibility with acrylic.

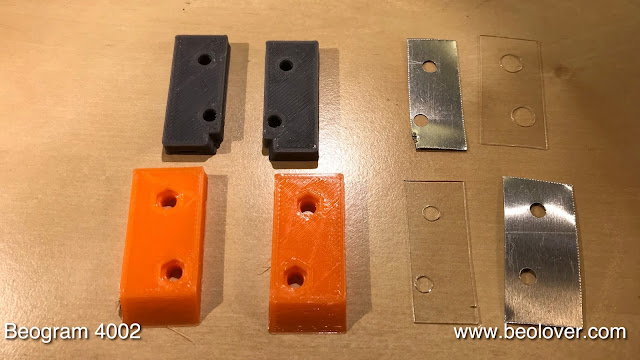

To ensure even clamping pressure, I used 3D-printed clamping parts. These parts, along with metal components to prevent bonding with the plexiglass, allowed for a secure fit while the glue dried.

Once the glue cured, I trimmed any excess material and reattached the aluminum trim using 3M 300LSE laminating tape. Locking pliers held everything securely in place for a day, ensuring a strong bond.

The final result was a nearly invisible repair, with the patches blending seamlessly into the hood.

To address scratches on the hood’s surface, I performed a multi-step polishing process, starting with 320-grit sandpaper and progressing through increasingly finer grits.

This restored the hood to a like-new shine.

Lastly, I replaced the worn rubber bumpers with sections of a 2mm O-ring.

These new bumpers ensured the hood sat level when closed. With these repairs, the hood is now restored to excellent condition.