I recently began restoring a Beogram 4002 (Type 5513) turntable for an Australian customer who purchased it on eBay. The turntable arrived in poor condition.

My initial evaluation is documented here.

This post details the unit’s restoration, excluding the dust cover, which will be covered separately.

I began with the DC platter motor, as is customary, since the bearing lubrication process requires a few days. Here’s the motor after removal:

Disassembling the motor allowed me to access the bearings:

The small, donut-shaped components on the black pad in the front are the bearings. I submerged these in motor oil and created a vacuum. The immediate appearance of bubbles indicated that air was being drawn out of the porous Oilite bearing material:

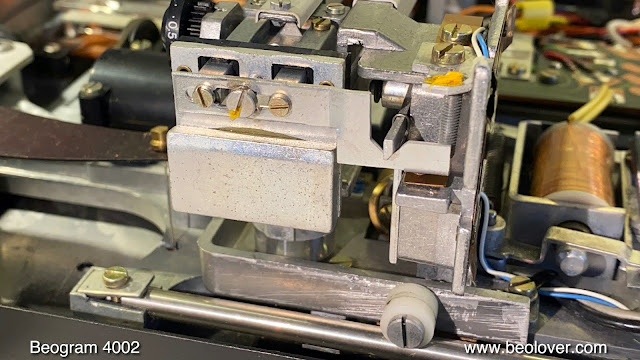

Fresh oil can enter the bearing thanks to the air being expelled. I concentrated on other parts of the turntable while this procedure was running. The arm lowering mechanism was the first thing I fixed. Hardened lubricants frequently cause it to become clogged. It is shown installed in this image:

I disassembled the moving components

and cleaned and re-lubricated them:

After reinstalling the mechanism, I removed the sensor arm assembly. Here’s a view of it from the back:

To re-lubricate the pivot point, I detached the damper-to-arm linkage:

I discovered that the double-sided tape securing the arm lowering limit “skid plate” had deteriorated while I was working on the assembly:

After removing the old tape and reinstalling the arm assembly, I used epoxy to reattach it to the arm base:

I replaced the tracking sensor’s incandescent bulb with an LED-based solution while I was working on the carriage. The original lamp housing is depicted here in place:

The aperture in charge of the tracking feedback is visible in this image after the aperture has been removed:

The LED-based Beolover substitute and the original bulb are shown here:

I secured the replacement in place and soldered the wires to the carriage’s PCB:

Replacing the fragile carriage pulley was the last step in repairing the carriage mechanism.

with a precisely machined aluminum component and a new belt:

Rebuilding the electronics was the next step. The main board is shown in its initial state in this image:

All of the electrolytic capacitors, the platter sensor transistor, the RPM trimmers, and the RPM relay were replaced with modern equivalents:

The RPM area is shown in this image with the new, sealed relay and 25-turn trimmers for precise and dependable RPM adjustment:

After that, I concentrated on the output board:

I changed the output grounding relay and the capacitor that determines its time constant on this board (to delay the relay action until the needle touches the grooves). Additionally, in case of a hum problem, I added a switch that allows for the connection of system and signal grounds (the red switch in front of the black cable jack):

The main reservoir capacitor that regulates the power rail is another crucial component to replace. It frequently deviates from specifications and/or leaks:

I installed my two single capacitor replacement assembly because this 4002 included a double capacitance unit to enable a potential future 4-channel CD-4 upgrade. These dual caps are no longer offered. The smaller 1000uF unit is intended for the CD-4 board if it is ever installed, while the larger capacitor (4700uF) is for the main PCB. I typically put a 20k bleeder resistor between the CD-4 power rail and GND to ensure that the 1000uF capacitor discharges correctly after the deck is unplugged:

I changed the remaining incandescent lights after finishing the boards. The sensor arm bulb was the first to be replaced with a flex-PCB-based drop-in substitute that featured a warm-white LED and a bypass resistor to boost the current to the level of a light bulb. This is required to guarantee that the record detection circuitry identifies the LED as a “valid light bulb” and permits arm descent. This safety element guards against the arm unintentionally dropping if the bulb burns out. The initial bulb and the replacement assembly are shown in this image:

And with the bulb out:

and after installation:

[ ](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEg9POU2cNdTIFSbjtZHsAuweR42ZMa986hx

](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEg9POU2cNdTIFSbjtZHsAuweR42ZMa986hx